Ferrite Testing

Ferrite testing is an NDT method used to determine the ferrite content in austenitic and duplex stainless steels. The ferrite number (FN) and/ or ferrite percent (Fe%) are normally determined in welding procedures as a control of material corrosion susceptibility, mechanical properties, service suitability, and reliability. It must be noted that there is a difference between the unit measurement of ferrite number and ferrite percent. The Schaeffler and Delong Diagram may be referred to as a reference only.

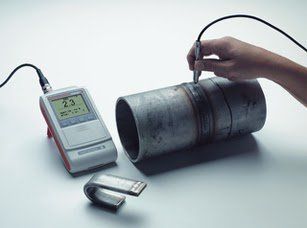

Ferrite testing is commonly performed on welds, weld overlays, and wrought materials. Surface preparation and cleanliness is important to ensure test result accuracy, and testing is not recommended on material temperatures greater than approximately 125°F (52°C).